| Deltaribs - unprecedented freedom of structural shapes | Home > Deltaribs structural |

|

Structural |

||||||||||||||

| As each rib is unique and custom-made, it can be

designed for the structural capacity that is locally needed, even if

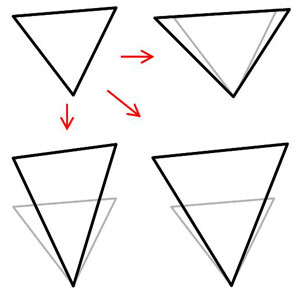

varies along the rib. Deeper ribs lead to more stiffness in that

direction, wider ribs in the direction perpendicularly to it.

Spatially curving network structures - unlike frame structures -

lead as by default to its members acting in torque, and the

Deltaribs' closed cross section is particularly apt for that. In

addition, the ribs also resist bending in all directions.

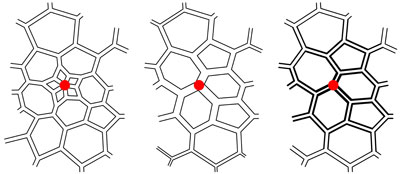

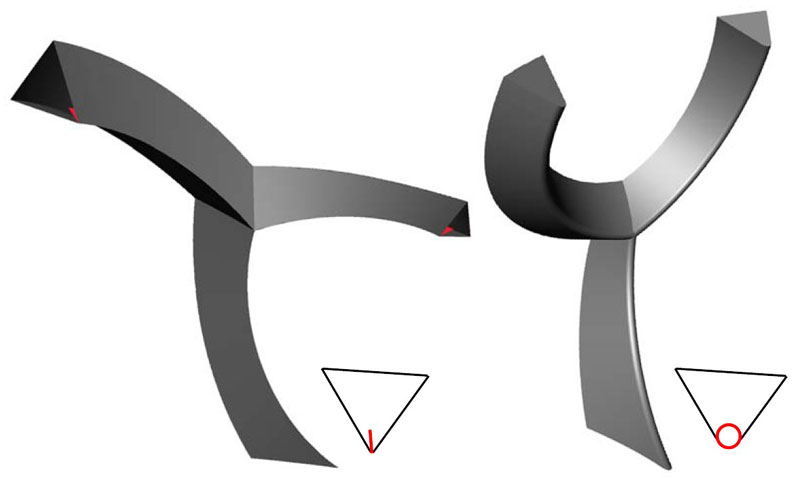

Strength and stiffness of the ribs are dependent on the size of the cross section and the plate thickness, and can be increased by incorporating a steel plate or circular bar or tube is included in the edge of a rib, where it is most effective. On a more global level, the structural capacity of the network is affected by its density. For instance in heavily loaded zones nearby supports, rib spacing could be reduced, whereas made more spacious elsewhere. |

Increased capacity by making the rib's cross section wider and/or deeper.  Increased structural capacity by a higher grid density, by a greater beam size, and through thicker plates. |

|

| Increased capacity with an internal planar or tubular 'flange'. |

Copyright 2011 Martijn Veltkamp, MoreThanStructures. All rights reserved. Contact.